How to shepherd a company’s technologies for growth

Thursday, February 16, 2023 at 11:10AM

Thursday, February 16, 2023 at 11:10AM CTO interviews part 3: Dr Julie Eng

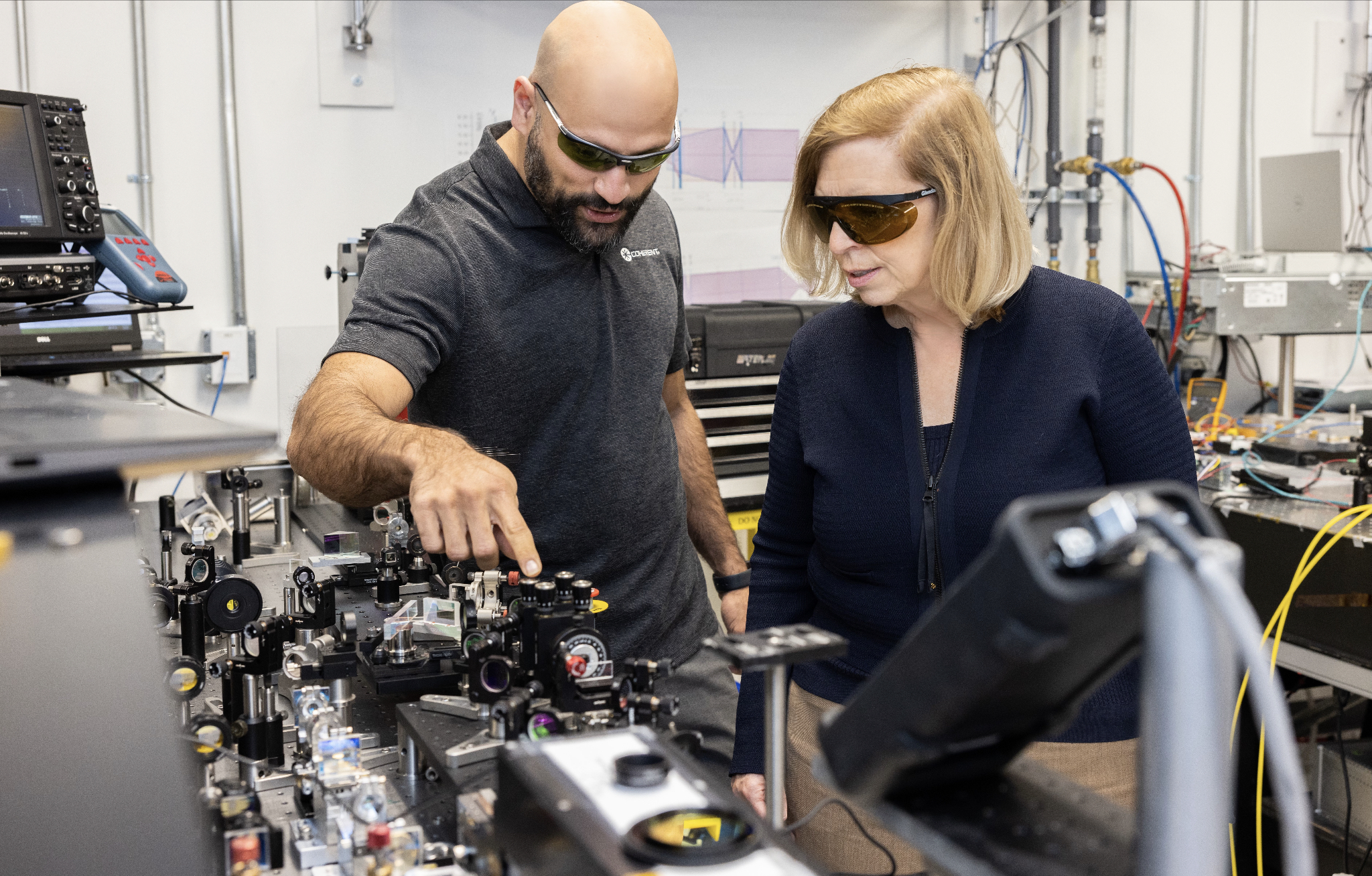

- Eng is four months into her new role as CTO of Coherent.

- Previously, she headed Finisar’s transceiver business and then the 3D sensing business, first at Finisar and then at II-VI. II-VI changed its name to Coherent in September 2022

- “CTO is one of these roles that has no universal definition,” says Eng

Dr Julie Eng

Dr Julie Eng

Julie Eng loved her previous role.

She had been heading II-VI’s (now Coherent’s) 3D sensing unit after being VP of engineering at Finisar’s transceiver business. II-VI bought Finisar in 2019.

She moved across to a new 3D sensing business while still at Finisar. The 3D sensing unit was like a start-up within a large company, she says.

II-VI and Finisar had been competitors in the 3D sensing market. Eng headed the combined units after Finisar’s acquisition.

She enjoyed the role and wasn’t looking to change when the CEO asked her to become Coherent’s CTO.

“To become CTO of the new Coherent - to help define the future of this company which is a five-plus going on six billion dollar company - that is pretty exciting,” says Eng.

The “New” Coherent

Coherent combines a broad portfolio of technologies from II-VI, Finisar, and the firm Coherent which II-VI acquired in 2022.

Just within lasers, Coherent’s portfolio spans from devices 1mm wide that are sold into mobile phones to the former Coherent’s lasers that are meters wide and used for OLED manufacturing.

Being CTO is different from Eng’s line-management roles, which had set, tangible annual goals.

Her role now is to shepherd the company’s technologies and grow the business over the long term.

Eng has been familiarising herself with the company’s technologies. To this aim, Eng is drawing on deep technological expertise across the company’s units.

Luckily, lasers are already covered, she quips.

“One of the things that I always somehow had a knack for is interacting with customers, sensing opportunities, and then figuring out how our technologies can help customers solve their problems,” says Eng.

It is a skill she successfully transferred to the consumer - 3D sensing - business but now it will be needed on a broader scale.

Eng is also making connections across technology units within the company as she seeks to identify new technologies and new market opportunities.

Her CTO role also allows her to engage with every Coherent customer across the company’s many markets.

She admits being CTO is challenging. One issue is grappling with the breadth of technologies the company has. Another is how to assess her works’ impact.

She and the CEO have discussed how best to use her time to benefit the company. Eng has also talked to other companies’ CTOs about the role and what works for them.

“It’s very interesting; CTO is one of these roles that has no universal definition,” says Eng.

Technologies to watch

Eng highlights several developments when asked about noteworthy technologies.

For communications, this is the year when 200 gigabits per lane will likely be achieved.

“The first transceivers I worked on were [SONET/SDH] OC-3 which is 155 megabits per second (Mbps),” she says. “Is wasn’t even a transceiver back then; it was discrete transmitters and receivers.”

That the industry has accelerated technology to achieve multiple lanes of 200 gigabit-per-second (Gbps) in a pluggable module is remarkable, she says.

Eng also notes Coherent’s work on a continuous-wave laser integrated with a Mach-Zehnder modulator - a DMZ - to enable 200 gigabits per lane.

The company is also active in life sciences and health monitoring. Communications, especially during the pandemic, showed its importance in people’s lives. “But life sciences and health-related products have a much more direct impact on people,” says Eng. “That is not something I’ve had direct exposure to.”

Life sciences and health monitoring is a segment where optics and optical devices will play a growing role over time.

Medical devices often originate in research environments such as hospital labs before becoming medical instruments. From the lab, they go to clinical. “What we are talking about here is going from lab to clinical to therapeutics,” she says.

The US Chips Act also heartens Eng: “It was about time for the US to prioritise semiconductors.”

Low-power coherent DSPs

Coherent and ADVA jointly developed a low-power coherent digital signal processor (DSP) and optics design for a 100-gigabit ZR (100ZR) design that fits within a QSFP28 module.

“We have an internal DSP team, and they are developing DSPs for the coherent optics market,” says Eng, adding that having the design team gives Coherent options.

Meanwhile, the debate about direct detection technology versus coherent optics continues.

As optical lane speed increases from 100 gigabits to 200 gigabits, the question remains what reach will direct detection achieve before running out of steam?

With 200 gigabits per lane, 800 gigabit modules can be achieved using four optical lanes, while for 1.6 terabits, eight lanes will be used.

Eng is confident that direct detection will support 10km at these speeds. Beyond 10km, direct detection becomes much more of a challenge, and coherent is an option.

“The real question is will coherent optics meet the size, cost and power consumption expectations of the data centre customers on a timeframe that meets their needs,” says Eng.

Having in-house DSP technology means Coherent can undertake design trade-offs and make the right decisions, she says.

After 1.6 terabits, the design options include increasing the lane rate, using more than eight channels or adopting more advanced modulation schemes.

“We look at the application, the timeline that the product needs to be released, the readiness of the technology, we do measurements - simulations - and we make objective decisions based on the results,” says Eng.

Whatever the prevalent technology is, says Eng, that technology will continue to improve since that is the livelihood of many companies.

“All of us, as an industry, are going to put our all into extending the technologies we currently have,” says Eng. So, when it comes to direct detection versus coherent, everyone will push direct detect technology as far as possible.

“Getting up to 1.6 terabits [using direct detect], that is pretty good,” says Eng. “That is going to last us a pretty long time.”

Materials

Coherent’s toolbox of material systems covers indium phosphide, silicon photonics, and gallium arsenide. It also has silicon carbide, a semiconductor suited for high-power transistors used for power electronics applications.

“We have all the technologies, we use the best technology for the product, and we use good engineering judgement,” says Eng.

Rather than favour indium phosphide or silicon photonics, Eng’s segmentation starts with whether the design is directly modulated or externally modulated.

Until now, up to 50 gigabits per lane has been well served by directly modulated lasers. This has used indium phosphide or, in the case of VCSELs, gallium arsenide.

“In general, directly modulated is the lower cost because the die is tiny, and often it is the lowest power,” says Eng.

But increasing the speed beyond 50Gbps gets more complicated with directly modulated lasers. This is where externally modulated lasers come in.

“Once you are already talking about an externally modulated solution, we start looking at the trade-offs between indium phosphide and silicon photonics,” says Eng.

The laser remains indium phosphide, so the bake-off concerns the modulator and the passive optics.

What indium phosphide brings is better electro-optics performance, while silicon photonics brings the benefits of integration.

“So if there is a high-lane count - lots of passives - or an opportunity to use one laser over multiple modulators, these can be complicated designs, and silicon photonics can help reduce the size,” says Eng.

Pluggables and co-packaged optics

With 200 gigabits per lane becoming available, there is a clear roadmap for 800-gigabits and 1.6-terabit pluggables.

“Customers like pluggables, and I don’t think people should underestimate that,” says Eng, adding that continued innovation will extend their lifetime.

“There are flyover cables between the switch ASIC and the modules, vertical line cards have been proposed, and we have shown board-mounted optical assemblies,” she says.

At some point, co-packaged optics may be the right solution, says Eng. But that will depend on the application’s specification, issues such as bandwidth, size, cost, power consumption and reliability.

“People will only transition to optical input-output when extending pluggables doesn’t make sense anymore,” says Eng. “I think it is probably five-plus years away, but there are probably error bars on that.”

Coherent’s activities include using indium phosphide manufacturing for external laser sources for co-package optics. “And we are working on silicon photonics,” she says.

Coherent is also working on co-packaging VCSELs with high-performance chips. “Not all applications require a 2km reach,” she says.

The coming decade’s opportunities

Eng’s thoughts about the growth opportunities for the coming decade are, not surprisingly, viewed through Coherent’s markets focus.

She highlights four segments: communications, industrial, instrumentation, and electronics.

Fibre-optics communications will continue to grow with bandwidth. The opportunities for innovation include datacom and coherent optics.

She also notes growing interest in free-space optics and satellite communications.

“I see money being spent on that and maybe that is a place where someone like ourselves, with a lot of optics as well as bigger lasers, can play a role,” says Eng.

Precision manufacturing uses lasers in the industrial segment. Eng cites cutting, welding and marking as examples.

“We have elements used for battery manufacturing which is increasing due to electric cars,” she says.

Excimer lasers are also used for OLED and microLED display manufacturing.

“We even have optics in extreme UV steppers [used for advanced process node chip manufacturing],” she says.

For instrumentation, much of the growth is around health life sciences. Coherent makes optics that are used inside PCR testers for COVID-19. It also has engineers working on solid state lasers used for flow cytometry (the sorting of cells). She also cites gene sequencing equipment and medical imaging.

Coherent’s electronics segment refers to the consumer market. Growth here for optics and lasers include AR/VR goggles and the metaverse, wearable health monitoring, and automotive.

For automotive, lasers are used for lidar and in-cabin sensing, such as driver and passenger monitoring.

Silicon carbide is also a growth market, and its uses include the wireless market and power devices for electric vehicles.

“I like the communications market, which we see as growing, but for us, with such a broad portfolio, there are many of these other markets and products that I see as exciting for the remainder of this decade,” says Eng.

Reader Comments