A coherent roadmap for co-packaged optics

Sunday, March 24, 2024 at 10:09PM

Sunday, March 24, 2024 at 10:09PM Is coherent optics how co-packaged will continue to scale? Pilot Photonics certainly thinks so.

Part 1: Co-packaged optics

Frank Smyth

Frank Smyth

Frank Smyth, CTO and founder of Pilot Photonics, believes the firm is at an important inflection point.

Known for its comb laser technology, Pilot Photonics has just been awarded a €2.5 million European Innovation Council grant to develop its light-source technology for co-packaged optics.

The Irish start-up is also moving to much larger premises and is on a recruitment drive. “Many of our projects and technologies are maturing,” says Smyth.

Company

Founded in 2011, the start-up spent its early years coupled to Dublin City University. It raised its first notable investment in 2017.

The company began by making lab instrumentation based on its optical comb laser technology which emits multiple sources of light that are frequency- and phased-locked. But a limited market caused the company to pivot, adding photonic integration to its laser know-how.

Now, the start-up has a fast-switching, narrow-linewidth tunable laser, early samples of which are being evaluated by several “tier-one” companies.

Pilot Photonics also has a narrowband indium-phosphide comb laser for optical transport applications. This will be the next product it samples.

More recently, the start-up has been developing a silicon nitride-based comb laser for a European Space Agency project. "The silicon nitride micro-resonator in the comb is a non-linear element that enables a very broad comb for highly parallel communication systems and for scientific applications," says Smyth. It is this laser type that is earmarked for the data centre and for co-packaged optics applications.

Smyth stresses that while still being a small company, the staff has broad expertise. “We cover the full stack,” he says.

Skills range from epitaxial wafer design, photonic integrated circuit (PIC)s and lasers, radio frequency (RF) and thermal expertise, and digital electronics and control design capabilities.

“We learned early on that it’s all well making a PIC, but if no one can interface to it, you are wasting your time,” says Smyth.

Co-packaged optics

Co-packaged optics refers to adding optics next to an ASIC that has significant input-output (I/O) data requirements. Examples of applications for co-packaged optics include high-capacity Ethernet switch chips and artificial intelligence (AI) accelerators. The goal is to give the chip optical rather than electrical interfaces, providing system-scaling benefits; as electrical signals get faster, their reach shrink.

The industry has been discussing co-packaged optics for over a decade. Switch-chip players and systems vendors have shown prototype designs and even products. And more than half a dozen companies are developing the optical engines that surround, and are packaged with, the chip.

However, the solutions remain proprietary, and while the OIF is working to standardise co-packaged optics, end users have yet to embrace the technology. In part, this is because pluggable optical modules continue to advance in data speeds and power consumption, with developments like linear-drive optics.

The ecosystem supporting co-packaged optics is also developing. Hyperscalers will only deploy co-packaged optics in volume when reliability and a broad manufacturing base are proven.

Yet industry consensus remains that optical I/O is a critical technology and that deployments will ramp up in the next two years. Ethernet switch capacity doubles every two years while AI accelerator chips are progressing rapidly. Moreover, the number of accelerator chips used in AI supercomputers is growing fast, from thousands to tens of thousands.

Pilot Photonics believes its multi-wavelength laser technology, coupled with the intellectual property it is developing, will enable co-packaged optics based on coherent optics to address such scaling issues.

Implementations

Co-packaged optics uses optical chiplets or 'engines' that surround the ASIC on a shared substrate. The optical engines typically use an external laser source although certain co-packaged optics solutions such as from Intel and Ranovus can integrate the laser as part of the silicon-photonics based optical engine.

Designers can scale the optical engine’s I/O capacity in several ways. They can increase the number of fibres connected to the optical engine, send more wavelengths down each fibre, and increase the wavelength’s data rate measured in gigabits per second (Gbps).

In co-packaged optics designs, 16 engines typically surround the chip. For a 25.6-terabit Ethernet chip, 16 x 1.6-terabit engines are used, each 1.6-terabit engine sending a 100Gbps DR1 signal per fibre. The total fibres per engine equals 32: 16 for the transmit and 16 for the receive (see table).

|

Switch capacity/Tbps |

Optical engine/Tbps |

Optical engines |

Data rate/fibre |

No. fibres/ engine* |

|

25.6 |

1.6 |

16 |

100G DR, 500m |

32 |

|

25.6 |

3.2 |

8 |

100G DR, 500m |

64 |

|

51.2 |

6.4 |

8 |

400G FR4, 2km |

32 |

|

102.4 (speculative) |

6.4 |

16 |

400G FR4, 2km |

16 |

|

102.4 (speculation) |

12.8 |

8 |

400G FR4, 2km |

32 |

*Not counting the external laser source fibre.

Broadcom’s co-packaged optical approach uses eight optical engines around its 25.6-terabit Tomahawk 4 switch chip, each with 3.2Tbps capacity. For the Tomahawk 5, 51.2-terabit Bailly co-packaged optics design, Broadcom uses eight, 6.4Tbps optical engines, sending 400-gigabit FR4, or 4-wavelength coarse WDM wavelengths, across each fibre. Using FR4 instead of DR1 halves the number of optical engines while doubling overall capacity.

The co-packaging solutions used in the next-generation 102.4-terabit switch chip are still to be determined. Capacity could be doubled using twice as many fibres, or by using 200-gigabit optical wavelengths based on 112G PAM-4 electrical inputs, twice the speed currently used.

But scaling routes for the generation after that - 204.8-terabit switch chips and beyond - and the co-packaged optics design become unclear due to issues of dispersion and power constraints, says Smyth.

Scaling challenges

Assuming eight engines were used alongside the 200-terabit ASIC , each would need to be 25.6Tbps. The fibre count per engine could be doubled again or more wavelengths per fibre would be needed. One player, Nubis Communications, scales its engines and fibres in a 2D array over the top of the package, an approach suited to fibre-count growth.

Doubling the wavelength count is another option but adopting an 8-wavelength CWDM design with 20nm spacing means the wavelengths would cover 160nm of spectrum. Over a 2km reach, this is challenging due to problems with dispersion. Narrower channel spacings such as those used in the CW-WDM MSA (multi-source agreement) require temperature control to ensure the wavelengths stay put.

Keeping the symbol rate fixed but doubling the data rate is another option. But adopting the more complex PAM-8 modulation brings its own link challenges.

Another key issue is power. Current 51.2-terabit switches require 400mW of laser launch power (4 x 100mW lasers) per fibre and there are 128 transmit fibers per switch.

"Assuming a wall plug efficiency of 20 per cent, that is around 250W of power dissipation just for the lasers," says Smyth. "Getting to 4Tbps per fibre appears possible using 16 wavelengths, but the total fiber launch power is 10 times higher, requiring 2.5kW of electrical power per switch just for the lasers."

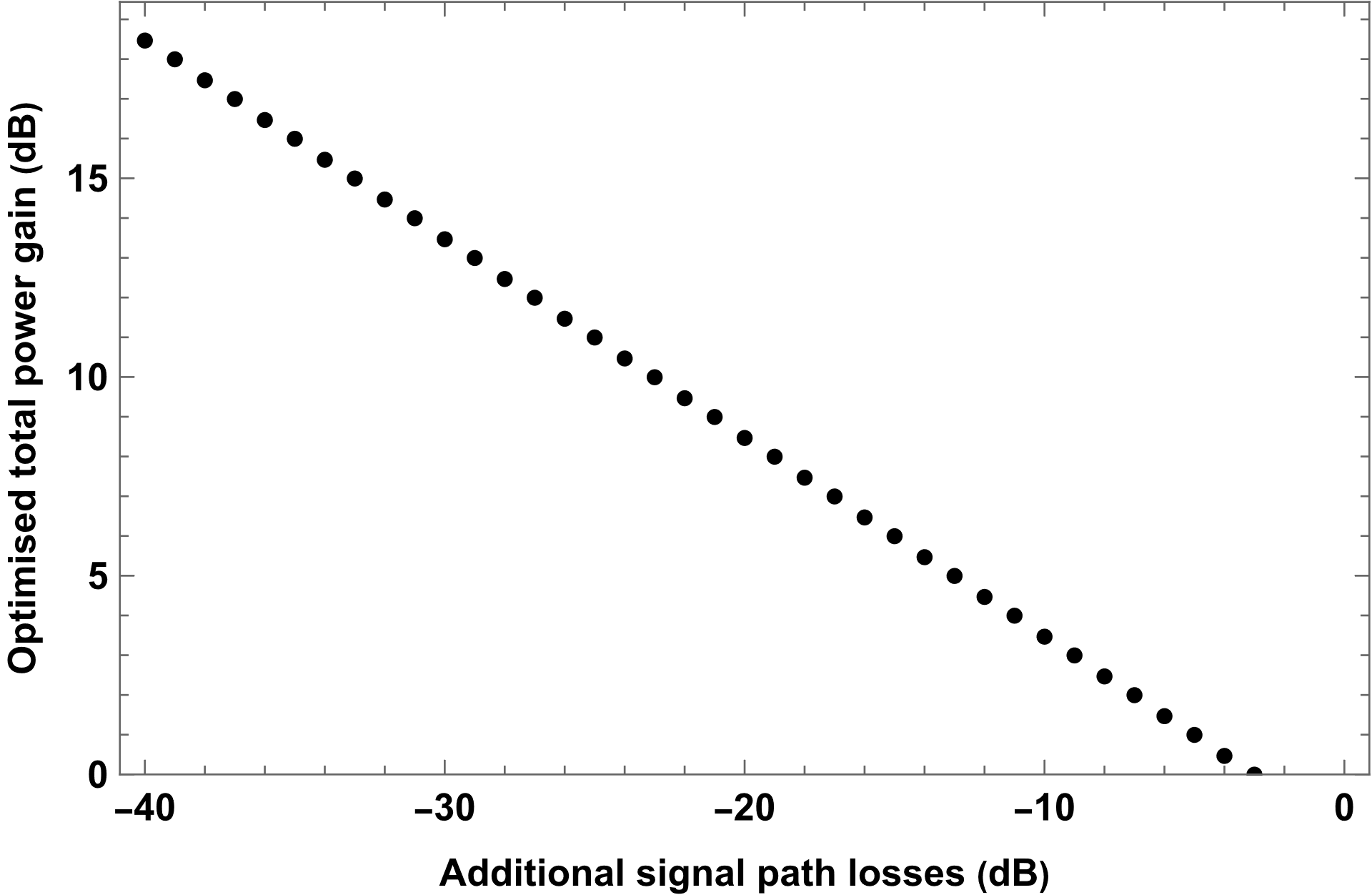

In contrast, single-polarisation coherent detection of 16-QAM signals through a typical path loss of 24dB could match that 4Tbps capacity with the original 250W of laser electrical power, he says.

The optimised total laser power improvement for coherent detection versus direct detection as a function of the additional losses in the signal path (the losses not also experienced by the local oscillator). Source: Pilot Photonics

The optimised total laser power improvement for coherent detection versus direct detection as a function of the additional losses in the signal path (the losses not also experienced by the local oscillator). Source: Pilot Photonics

Coherent detection is associated with a high-power digital signal processor (DSP). Are such chips feasible for such a power-sensitive application as co-packaged optics?

Coherent detection adds some DSP complexity, says Smyth, but it has been shown that for pluggable-based intra data centre links using 5nm CMOS silicon, 400-gigabit coherent and direct-detection are comparable in terms of ASIC power but coherent requires less laser power.

"Over time, a similar battle will play out for co-packaged optics. Laser power will become a bigger issue than DSP power," he says.

The additional signal margin could be used for 10km links, with tens of terabits per fibre and even 80km links at similar per-fibre rates to current direct detection.

"We believe coherent detection in the data centre is inevitable," says Smyth. "It’s just a question of when."

Comb-based coherent co-packaged optics

Coherent co-packaged optics brings its own challenges. Coherent detection requires alignment between the signal wavelength and the local oscillator laser in the receiver. Manufacturing tolerances and the effects of ageing in simple laser arrays make this challenging to achieve.

“The wavelengths of a comb laser are precisely spaced, which greatly simplifies the problem,” says Smyth. “And combs bring other benefits related to carrier recovery and lack of inter-channel interference too”.

Pilot Photonics' comb laser delivers 16 or 32 wavelengths per fibre, up to 8x more than existing solutions. Smyth says the company intends to fit its comb laser inside the OIF's standardised External Laser Source pluggable form-factor,

The start-up is also developing a coherent ring resonator modulator for its design. The ring modulator is tiny compared with Mach-Zehnder interferometer modulators used for coherent optics.

Pilot Photonics is also developing IP for coherent signal processing. Because its comb laser locks the frequency and phase of the wavelengths generated, the overall control and signal processing can be simplified.

While it will offer the comb laser, the start-up does not intend to develop the DSP IC nor make optical engines itself.

“A strategic partnership with a company with its own manufacturing facilities would be the most effective way of getting this technology to market,” says Smyth.

Reader Comments