A start-up that has been active for a year has dropped its state of secrecy to reveal it is already shipping its first optical transceiver product.

The company, DustPhotonics, is backed by private investors and recently received an undisclosed round of funding that will secure the company’s future for the next two years.

Product plans

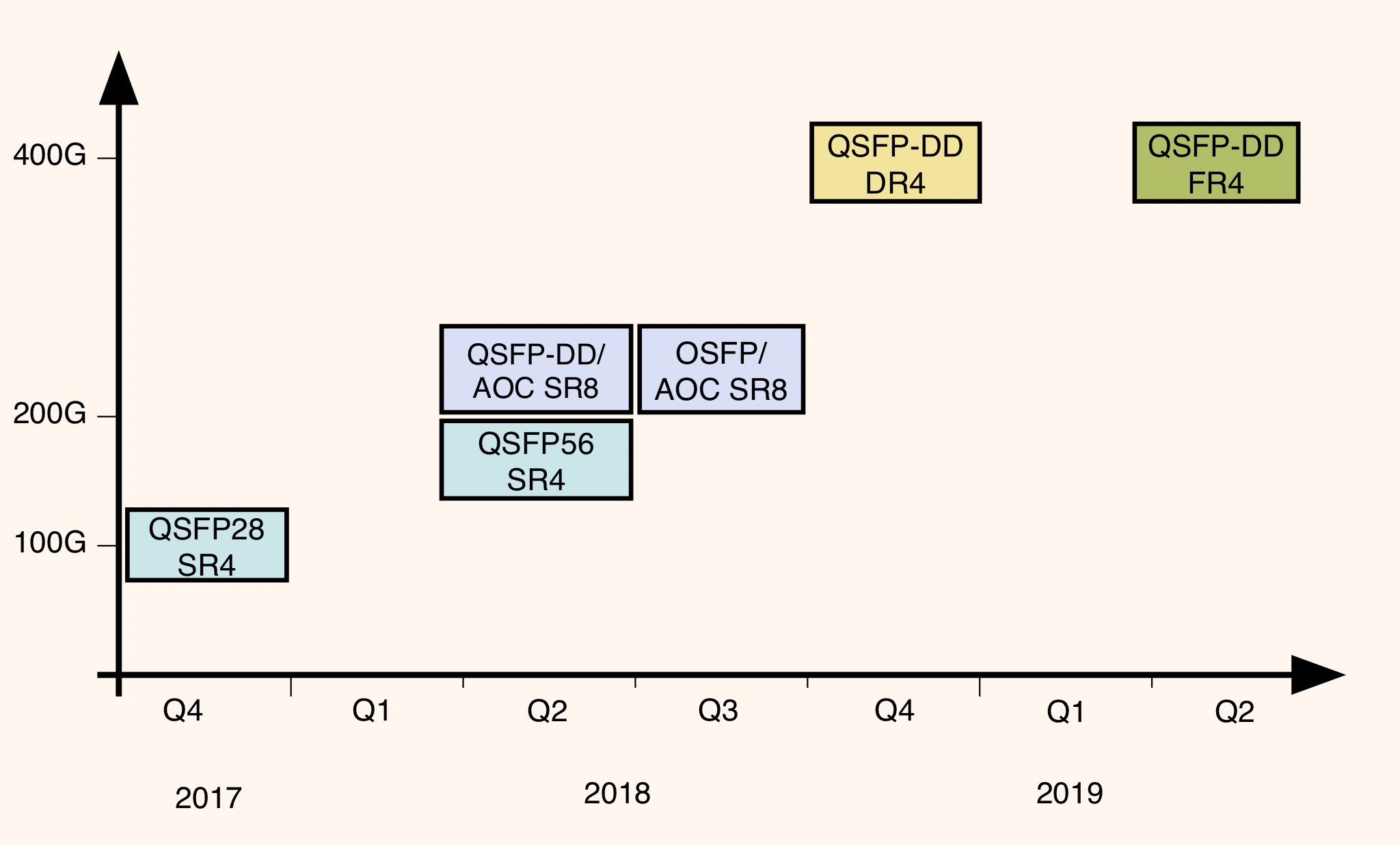

DustPhotonics' first product is the multi-mode 100m-reach 100GBASE-SR4 QSFP28. The company will launch its first 400-gigabit optical modules later this year.

Ben Rubovitch

Ben Rubovitch

“We probably are going to be one of the first to market with [400-gigabit] QSFP-DD and OSFP multi-mode solutions,” says Ben Rubovitch, CEO of DustPhotonics.

The start-up has developed 50 gigabit-per-lane technology required for higher-speed modules such as the QSFP56, QSFP-DD and OSPF pluggables. The QSFP-DD form factor is designed to be backwards compatible with the QSFP and QSFP28 and is backed by the likes of Facebook and Cisco, while the OSFP is a new form factor supported by Google and switch maker Arista Networks.

DustPhotonics chose the 4-lane 25-gigabit QSFP28 to prove the working of its 50 gigabit-per-lane technology. “The reason we did that is that the PAM-4 chipsets weren’t ready when we started,” says Rubovitch. “So we invested the first year solving the production issues and the optical interface and used the QSFP28 as the platform.”

The challenge with a 50 gigabit-per-lane optical interface is that the photo-detector aperture used is smaller. “So on our QSFP28 we used a small photo-detector to prove the optical solution,” says Rubovitch.

The start-up is now developing faster speed multi-mode designs: a 200-gigabit QSFP56 pluggable, a 400-gigabit QSFP-DD implementing the 400GBASE-SR8 standard and a similar active optical cable variant; products that it hopes to sample in the second quarter of this year. This will be followed by similar SR8 implementations using the OSFP.

DustPhotonics' optical product roadmap. Source: Gazettabyte/ DustPhotonics.

DustPhotonics' optical product roadmap. Source: Gazettabyte/ DustPhotonics.

DustPhotonics is also adapting its optical packaging technology to support single-mode designs: the 500m IEEE 400GBASE-DR4 and the 2km 400G-FR4, part of the 100G Lambda multi-source agreement (MSA). Both the DR4 and FR4 designs use 100-gigabit optical lanes.

Technology

Rubovitch says that despite the many optical transceiver players and the large volumes of modules now manufactured, pluggable optics remain expensive. “The front panel of a top-of-rack switch [populated with modules] costs ten times more than the switch itself,” he says.

DustPhotonics has tackled the issue of cost by simplifying the module’s bill of materials and the overall manufacturing process.

The start-up buys the lasers and electronic ICs needed and adds its own free-space optics for both multi-mode and single-mode transceiver designs. “It is all plastic-molded so we don’t use any glass types or any integrated lasers and that simplifies much of the process,” says Rubovitch. Indeed, he claims the design reduces the bill of materials of its transceivers by between 30 and 50 percent.

The front panel of a top-of-rack switch [populated with modules] costs ten times more than the switch itself

DustPhotonics has also developed a passive alignment process. “We have narrowed the one accurate step - where we align the optics - to one machine,” says Rubovitch. “This compares to two steps ‘accurate’ and one step ‘align’ for active alignment.” Active alignment for a QSFP28 module takes ten minutes, he says, whereas DustPhotonics’ passive alignment process takes under a minute per module.

“There is also a previous manufacturing stage where we place the VCSELs and photo-detectors on a substrate itself and we don’t need accuracy here, unlike other solutions,” he says.

The overall result is a simpler, more cost-effective design. “We are already manufacturing in a volume production line and we see the numbers and how competitive we are, and it is going to create an even larger advantage at 400 gigabits,” says Rubovitch.

DustPhotonics’ passive alignment process takes under a minute per module

What next?

DustPhotonics is also developing embedded optics, where the optics are placed next to an ASIC, and even in-package designs where the optics and ICs are co-packaged.

Rubovitch says such technologies will be needed because of the very high power 100-gigabit electrical transceivers consume on a switch chip, for example, as well the silicon area they require; precious silicon real estate needed to cope with the ever-increasing packet-processing demands. “Bringing the optics very close [to the chip] can help solve those issues for the switch providers,” he says.

As Rockley Photonics’ CEO, Andrew Rickman, observed recently, combining optics with the switch silicon has long been discussed yet has still to be embraced by the switch chip makers. This explains why Rockley developed its own switch ASIC to demonstrate a complete in-packaged reference design.

Rubovitch agrees that the concept of optics replacing electrical interfaces has long been spoken of but that hasn’t happened due to copper speeds continuing to advance. There is already a 100 gigabit-per-lane solution that will meet the demands of the next generation of switch designs, he says: “It really depends on what is going to be the next leap: 200 gigabits or 400-gigabits.”

Using optics to replace electrical interfaces could come with the advent of 25 terabit switch silicon or maybe the generation after. “Or maybe something in between: 25 terabit solutions will start to move gradually to a more packaged solution or at least closer on-board optics,” concludes Rubovitch.